June 21, 2019 | Jayson Hotell

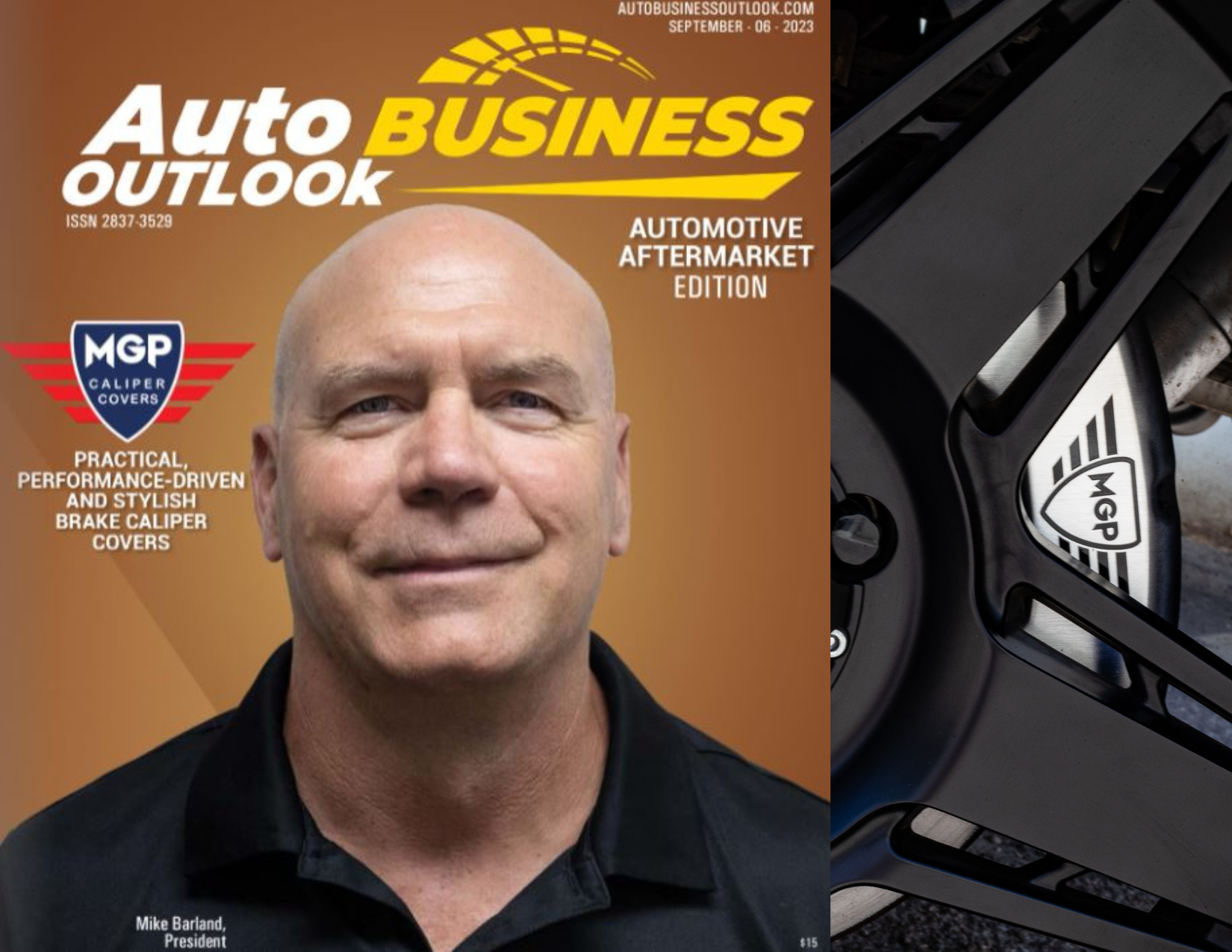

We take you behind the scenes in the process of making MGP Caliper Covers.

MGP makes custom caliper covers for any vehicle in the USA. Watch what the step by step process we take to ensure the highest quality!

MGP Caliper Covers are made in several steps.

- Engraving – The first step of our process is engraving the design of your choice directly onto the cover.

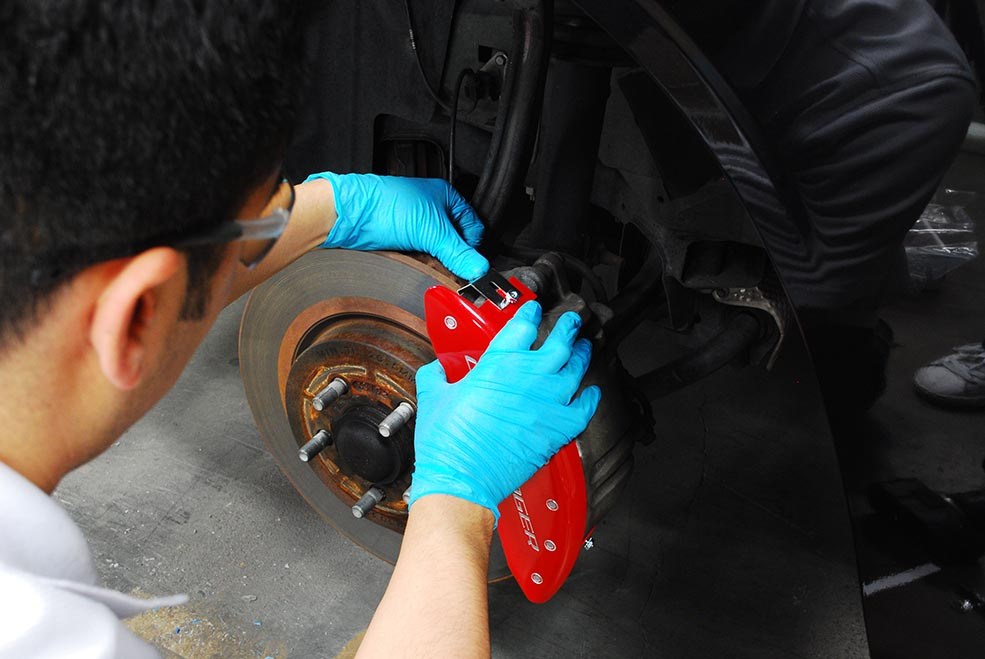

- Welding – Making it easy for you to install directly onto the caliper without removing them

- Buffing – To ensure the covers are smooth and have a nice finish

- Powder Coat / Paint – Adding that pop of color

- Paint fill – Manually paint filling the engraving with an accent color.